Description

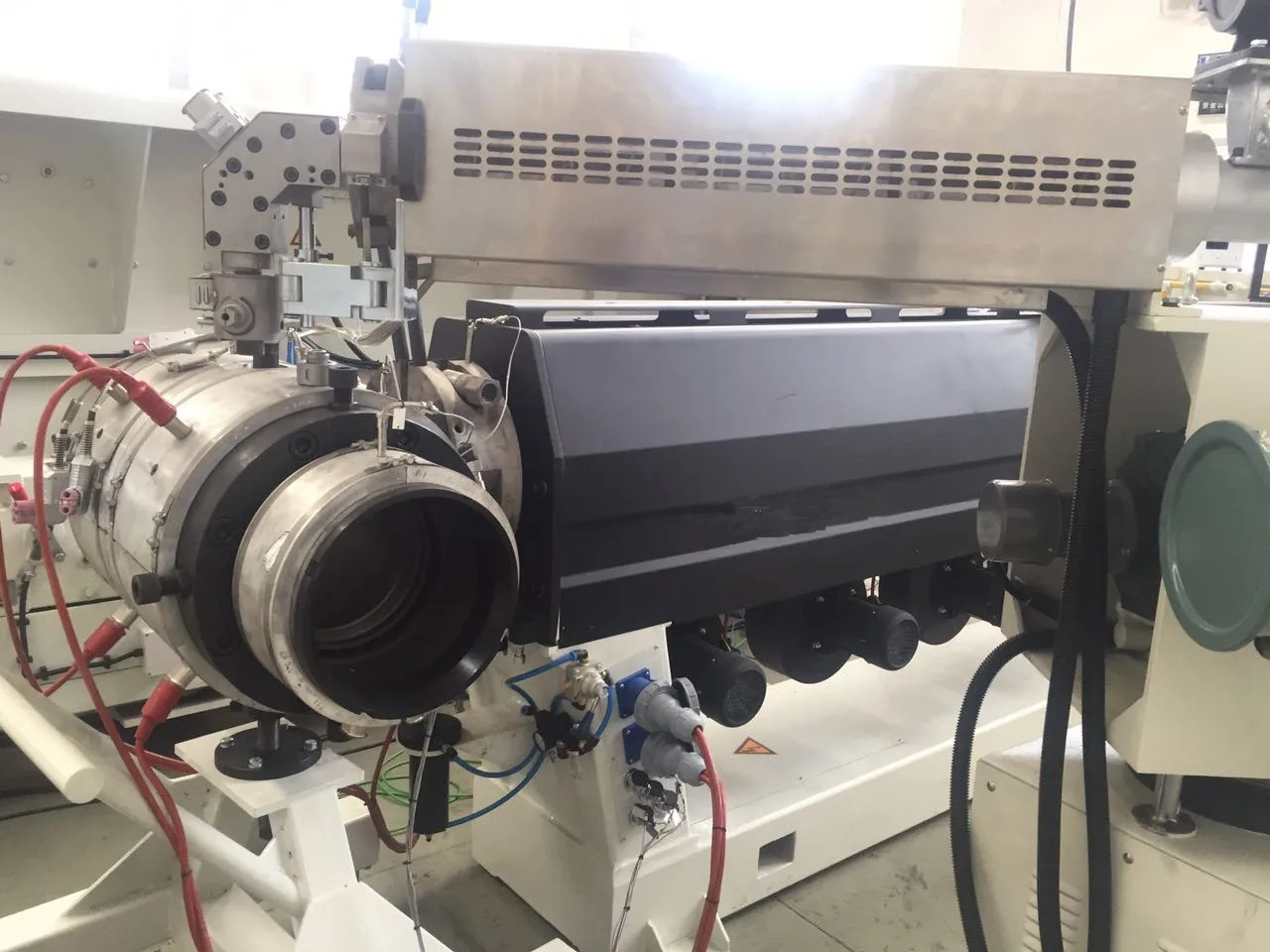

I SJ30 X 25 ~ SJ200 X 25 Plastic extruder

Structure feature:

– Integral frame has nice rigidity and intensity, made of high quality recetangle steel, easy for installation work.

– Screw & barrel are special designed, made of 38 CrMoAIA precision processing high quality alloy steel, with precision processing treatment, surface is nitrogen treated, nitrogen depth is within >0.5mm~<0.7mm, hardness is >940, brittleness is not big than grade 2.

– Suitable for use special screw to extruder compound of PVC, PE, LSHF (Low-smoke halogen-free), satisfy customers different technics requirements.

– Adopt high quality hardness gears (JHM series) special gearbox, which has advantage such as big capacity, high precision, low noise, high coefficient of safety, and long working life.

– The main extruder of Dia. 90~200 series adopt independent motor for oil pump circulation and cooling, which is more safe and reliable.

– (Optional part) Special designed material feeding device has drain out exit, it is convenient to change material during line stop, save time and material.

– Cross-head connection is “half-type”, easy for assembling work and it is reliable.

– Body heater has three types for customers’s choice:

1.) casting AI heater

2.) ceramic heater & cooper fin radiator

3.) new type induction heater

Main technical parameters:

| Type & Size | Screw Dia. (mm) | L/D ratio | Screw speed (rpm) | Main motor (kw) | Barrel heating power (kw) | Temp. contr. zones (body/cross head) | Max. output capacity (PVC) (kg/h) |

| SJ30X25 | 20 | 25:1 | 5-150 | 11 | 3.6 | 3/2 | 20 |

| SJ45X25 | 45 | 25:1 | 10-120 | 15 | 9 | 3/2 | 50 |

| SJ65X25 | 65 | 25:1 | 10-100 | 30 | 16 | 4/4 | 120 |

| SJ90X25 | 90 | 25:1 | 10-100 | 90 | 30 | 4/4 | 280 |

| SJ120X25 | 120 | 25:1 | 7-68 | 132 | 54 | 6/4 | 580 |

| SJ150X25 | 150 | 25:1 | 6-60 | 185 | 88 | 6/4 | 880 |

| SJ200X25 | 200 | 25:1 | 4-40 | 250 | 140 | 7/4 | 1100 |

II. SJ30 X 25 ~ SJ200 X 25 series insulation & sheathing extrusion production line

Application:

– This production line is used for producing PVC, PE, LSHF (Low-smoke halogen free) cable insulation layer or sheathing layer.

Main technical parmaters:

Extruder spec.: Dia 30, 45, 65, 90, 120, 150, 200 etc.

Screw parameters: L/D ratio: 25:1 or 30:1

Type: tapered screw, LSHF screw or BM type (user’s option)

Whole stainless steel cooling water tank: total length 12-32m (depends on types) unit end is equipped with telescopic water tank.

Traveling distance is 300-600mm

Caterpillar: TQD 100~4000 caterpillar puller (depend on actual type)

Line speed: 30m – 200m/min (depending on actual type)

Tke up and pay-off reels specification: PN500-PN5000 (depend on actual type)

Features:

– The line can be configured and combined flexibly depending on technological requirements, thus featuring easy use.

– Extruder main unit and puller are driven by Z4 DC motor (or frequency conversion motor), controlled by imported full-digital speed-control device.

– Extruder body and head are equipped with RKC temperature control instrument with control-accuracy < ±2°C.

– Pay-off & Take-up adopts new shaftless structure (portal type or gantry type), bobbin loading & unloading without crane.

– Large sheath machine unit adopts front and rear double-hauling, equipped with special synchronous control circuit, ensuring that the cables are not scratched and damaged un water tank.

– The line is controlled by PLC, featuring steady and reliable preformance. It is possible for users to adopt industrial computer (PC) and main-control touch screen.

– The line is centrally controlled, to realize automatic production.

III. TQD series pneumatic belt caterpillar

Application:

– Mainly for usage of wire and cable production line in single or in front and rear double haul-off purpose.

Structure and feature:

– Integral frame has nice appearance which is welded by high quality bending steel

– Equipment transmission is via motor – gearbox – gear reducer – up& low helical gear – hard drive structure, transmission is smooth, high loading capacity, easy maintenance.

– Whole series has more than 10 sizes from 200kg to 15000kg, two kinds of speed regulation structure of Z4 DC motor and frequency motor could be choose at customer’ needs.

– Equipped with electronical meter counter, real-time display line speed and length.

– Prepare transmission shaft structure, for matching production of laying up production line, armoring production line, and copper tape screen and lapping production line.

– Tension is controlled by magnetic powder clutch, use for front haul-off device of insulation and sheathing production line, tension is instantaneous adjustable, to prevent cable scrape in the water trough, and insure synchronization and diameter of cable.

– The small size caterpillar has whole frame with movable function, convenient for customer use to special technical requirement, and efficiently increase belt life.

-1-300x300.jpg)